For over a century now, we have grown accustomed to a single type of chemical synthesis: organic chemistry. And for a long time, regardless of the pollution it caused, the volatility of its processes, and the extremely low energy efficiency, we had been content with the output it provided us. After all – if it wasn’t broken, we thought, why fix it?

However, the trouble began when we realized that it was broken, and that – with each passing decade of endless contaminant emissions, toxic wastewater leaks, and poisoning of the soil – we were killing our planet. Greener alternatives were needed urgently, and it wasn’t just a matter of changing our materials, but also of improving our processes.

Process development is key in the creation of safer plants (see more about safer plants in a previous post) and better chemicals and materials, and it allows us to harness technology to make the necessary advancements for the sake of our industry’s future. Furthermore, the recent breakthrough discoveries in biochemistry open up much clearer paths towards the creation of better chemistries and safer manufacturing.

However, are these new processes and technologies efficient? Is the world ready to let go of the legacy organic synthesis processes that have served us so faithfully for so long… and are biochemical processes a replacement to organic chemistry processes, or actually a tool to be combined with them?

The problems with our current organic chemistry processes

We are aware of the main consequences of chemical contaminants: CO2 emissions and climate change, polluted water and damaged ecosystems, sick populations of humans and animals; however, very little is said of which specific aspects in our manufacturing processes cause these issues.

The problem begins at the very beginning of the chain: in an age of rapidly progressing technology, we are still creating our chemicals by using equipment and techniques that have been around for too long, from ages in which we were harming the planet and were unaware of it. Unfortunately, many companies are not willing to reinvest in revamping entire sections of their production plants and are content with simply meeting the minimum regulatory requirements (or in some cases, even looking for ways to circumvent them).

Even worse is that many companies are uneducated on polluting substances and believe themselves to be exempt from creating these compounds as byproducts in their production processes. The bottom line is that all types of manufacturing create pollutants, regardless of the industry (see this list for more information), and our first assumption should always be that our processes can be improved and made safer.

“It will always be better to prevent waste than to treat or clean it up after it has been created” is a key takeaway from green chemistry, and it is the philosophy to be applied if we wish to develop safer processes. Among the golden rules of green processes that should be followed, we encounter the following:

- Atom economy is one of the most important aspects behind synthesis processes, in which the main goal behind a reaction must be to consume as much of the reactants as possible when synthesizing products and thus eliminate undesirable waste products from the equation.

- Solvents and auxiliary agents are also a massive problem to keep an eye on: for, as much as chemistry has tried to reduce or eliminate them, solvents are a crucial part of most synthesis reactions, and they can often represent the largest proportion of a plant’s chemical substances. Finding the correct substances which can be recycled (instead of incinerating them, as many are) is critical if we want to develop safer processes.

- Energy efficiency is not only a problem of costs – it is also a problem of safety and of ecology, and many manufacturers are unaware of this. The majority of the existing plants in the world still use fossil fuels to power their reactors, heat exchangers, and other units, and this represents a risk in terms of pollution and potential volatility (explosions and fires). It is also well known that organic chemistry synthesis is all about raising temperatures and pushing pressures up to their limits to be able to break bonds; in other words, it is heavily energy-dependent. If we can use clean energy sources, as well as cleaner processes that can take place at ambient conditions of temperature and pressure, we can create safer chemical manufacturing plants.

- Using feedstocks of a renewable origin is also an indispensable shift towards cleaner chemistry. We are accustomed to fossil fuels for our organic chemistry processes; however, these are not only polluting but also being depleted with each passing year. A solution to this has already been presented, in the form of plant biomass and animal waste products (chicken feathers, for example). These represent a huge reduction in expenses to the plant and are harmless to the water, soil, and ecosystems in the production plant’s vicinity.

It is clear at this point that there are multiple ways of solving the “green process” problem that is affecting the industry, and that it is less a matter of having the tools than it is of having the will to use them.

However, there are two even more incredible secret weapons we possess on this road to optimizing our plants and integrating technology into our evolving organic chemistry synthesis processes that have not been mentioned yet: catalysis and biochemistry.

Catalyzing the manufacturing industry towards a new era

Chemical manufacturers are already familiar with catalysts, and there are few reactors that don’t already make use of these intriguing chemicals to direct and accelerate synthesis processes.

Yet, these substances do more than simply create more optimal conditions for a reaction to take place: by leveraging them in our chemical processes, we can control the parameters of conversion, yield, and selectivity within reactors, providing us with more advanced products and a greatly enhanced cost efficiency for our synthesis processes.

In fact, if we look past these advantages and study the reaction conditions alone, catalysts allow us to create safer plants with significantly reduced energetic consumptions (accomplished by lowering the activation energy required for the chemical transformation), and less potential for danger towards the workers and surroundings of a plant.

The increase in selectivity of a process within the reactor allows us to create advanced intermediate chemistries, which in turn are converted towards the final, desired products at a yield that can often approach the 100% mark – a perfect exchange of matter and energy with marginal amounts of energetic and material waste.

It is important to note that organic chemistry can find itself benefiting vastly from catalysis, as is the case with polymerization and other exothermic reactions that operate at potentially dangerous conditions. In fact, polymers can develop beneficial properties when created under catalytic conditions, and may be used as catalysts themselves in certain reactions.

The goal to implementing catalysis across the industry, thus accelerating organic chemistry towards safer and cleaner processes, is a very positive one, and one that is being achieved even now. With enough work and investment in research and development efforts, catalysts will always be the main ingredient in future organic chemistry synthesis.

Biochemistry, however? That’s another story to tell…

Biochemistry: combining the complex perfection of biology with the power of chemistry

Though relatively new, historically speaking, synthetic biology has allowed humanity to make enormous advancements in both science and engineering, simply by bringing an immense plethora of technologies, substances, and materials to the playing field that is the manufacturing industry.

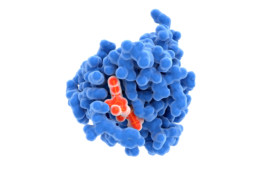

Biochemistry has been no exception, representing an important catalyst (no pun intended) in the growth of the chemical field in general: through the introduction of unprecedented and completely unique molecules, many manufacturers of advanced chemicals and breakthrough materials have designed the substances that are shaping our future.

However, the most interesting side to this field is the environmentally-friendly aspect of everything related to it: raw materials in biochemical synthesis are not contaminant or toxic; neither fossil fuels nor solvents are involved; processes take place in mild, ambient conditions; and it never involves a race towards creating the highest temperature and pressure, but of allowing life itself to form under the most adequate parameters.

Bioreactors – or fermenters – are incredibly different from the chemical reactors we are most familiar with. Inside them, we can find an entire biological system within a typically liquid carbohydrate medium: cells are grown in strictly controlled conditions of temperature, pH, partial oxygen pressure (although this depends on the cells being aerobic or anaerobic), foam control, optical density, and mixer rate (rpm). These conditions are further controlled by probes, introduced into the medium to ensure the correct functioning of the bioreactor, and to monitor the process of cell growth within the vessel.

Bioreactors are expensive to construct, and plants based on biochemistry can be extremely costly. However, highly-regulated companies, such as those in the food and drink, animal feed, and pharmaceutical spaces have already found benefits in using this type of equipment in their production plants.

Yet, it isn’t the exclusive use of biochemistry that represents a modern solution to the challenges we have faced in organic chemistry – the most attractive aspect of biochemistry is the fact that it can be integrated into an existing manufacturing process line, allowing us to harness natural molecules and combine them with organic chemistries, allowing us to design improved materials, such as films, ceramics, coatings, and drugs. Companies in this space, many of them using automation and machine learning to help optimize their processes, are seeing great success in their endeavors, and are already helping create the smartphones, computer screens, and spacecraft materials of the future.

In short, through the merging of the impressively powerful organic chemistry field and the safe, advanced nature of biochemistry, the chemical manufacturing industry is already accelerating rapidly towards a new era – one in which technology will significantly add value like never before.

“Organic chemistry synthesis processes are typically characterized by violence - it is a matter of applying brute force.

In biochemistry, however, we are using mild, safe processes to create living molecules; we are massaging life into existence.

For this reason, combined, both sciences can accomplish enormous feats.”

— Ryan Esner, Environmental Fluids CEO

In conclusion – it is a time of great promise for our industry. In the face of stricter regulations and the need for safer chemistry, we already have the solutions at hand. Through the combination of organic chemistry and biochemistry, we can create better products with improved processes, which are not volatile, expensive, or dangerous, and keep our planet and people safe.

Furthermore, these processes will make the best use of the technology available, and will most likely adapt seamlessly into the coming era of Industry 4.0, thanks to the potential that this brings. Finally, biocatalysts will essentially offer the best of both words: the extreme efficiency of catalysis, and the cleanliness of biochemistry.