The growing coalescence between biology and chemistry is one of the impressive new twists presently occurring in our industry; an amalgamation of two worlds that is benefiting from a blend of the best aspects in both sciences to create unprecedented materials and substances with novel properties.

Following a previous company post on the hybridization of biochemistry with organic chemistry, it is only logical to follow it with a closer view on one of the most attractive applications of synthetic biology in the chemical landscape – the creation of advanced materials.

The strength in a spider’s silk, the complex structure of a crustacean’s shell, the functional engineering of muscles: these are essential elements and machines of biology which execute their tasks faultlessly, counting on billions of years of evolution to have reached a level of incomparable efficiency and flawlessness that humanity is far from achieving with its own creations. Even now, with all of the technologies available, we are often unable to replicate the level of strength, flexibility, adhesion, and other structural and functional properties found in biological materials, and these have often been the bars we set as a level to strive towards.

Because of this, our creative minds have, for at least a century, been looking towards manufacturing bio-inspired materials, demonstrating success in inventions such as synthetic rubber, penicillin, body armor, and Velcro, to name a few. And now, in modern times, our technical capacities have allowed us to alter and transform the building blocks of life itself – cells, enzymes, and proteins.

Herein lies the intriguing side of biochemistry: nature has provided us the tools to apply and emulate into our own synthesis processes, and it has always been just a matter of discovering the way. Now, with the astounding scientific advancements being made and the rapid expansion of material diversity, we are finally developing the abilities to leverage nature into making better compounds with safer and less toxic processes than those offered by synthetic chemistry alone.

The enviable potential of biomaterials, and where we currently stand

In the face of a global shift in manufacturing and the fossil fuel industry due to the increasing global consciousness surrounding climate change and human health, it is the best time to be looking for alternatives that can represent renewable and sustainable alternatives in terms of materials. Thankfully, biological materials respond to this need in a remarkable way.

If you possess any kind of interest in the latest evolution of the synthetic biological and biochemical fields, you will have learned that there have been great developments in both fields in contemporary decades . For example, biopolymers have long demonstrated their utility and efficiency in biomedicine and therapeutics: we need only to study the recent biodegradable alternatives in drug delivery and in collagen healing dressings to note how incredibly useful biomaterials have become.

However, biomaterials have transcended from their beginnings as biomedical accessories – for example, we have since started to harness microorganisms for bioremediation, thus eliminating pollutant substances from water, soil and air; and the new breakthrough development of the synthetic version of antimalarial chemical, artemisinin, was named a “triumph” by many in the scientific community.

The potential of these materials is immense – by reprogramming cells to produce a specific type of molecule (which they wouldn’t normally synthesize), we can effectively create renewable, predictable factories of world-changing materials that can be used to take the fields of science into a new era.

Furthermore, thanks to the expansive knowledge and usage of bioreactors – which are able to work in milder, more controllable conditions than chemical synthesis reactors – as well as the integration of automatized technology into these processes, the creation of these state-of-the-art molecules is shaping up to be an activity as inexpensive and as time-efficient as anything seen currently in organic chemistry plants.

Even so, despite the incredible advances being achieved under the umbrella of biotechnology and synthetic biology, the most exciting event going on in these industries right now is their encounter with chemistry, resulting in an entirely new field of biochemistry that the industry had never before seen – hybrid biomaterials based on the best from both disciplines.

How the hybrid engineering of chemistry and biology is transforming materials science

As a result of climate change and the overall environmentally-aware response of our modern times, we are bound to stricter laws and higher expectations in the manufacturing industry.

Because of this, no matter how revolutionary or game-changing a chemical or material may be – adhesives, films, coatings, composites, or otherwise – it will always be bound to the regulations set by governmental agencies, and production may be forced to a halt if processes or technologies are found to be too toxic or polluting. As the head of a green chemical manufacturing company, it is precisely one of my responsibilities to help companies avoid getting caught in this situation.

Thankfully, an all-in-one solution is presenting itself with the evolving unification of synthetic biology and chemistry: now, companies will have the capability of creating the same materials they’ve always produced, but in cheaper, safer, and renewable environments, and with the help of natural biological systems.

It may sound incredible, but this is a situation that is rapidly becoming a reality across the globe, as monomer provision, higher-order polymerization, and the exploration of materials development space is further accessed on a level that was previously impossible under our traditional synthetic chemistry limitations. Simply put, we are engineering cells into what we want them to be, leveraging the wondrous architectural power of nature to build new nanoscale structures and turning them into tiny production plants, constructed solely to replicate hybrid materials through predictive design.

The aerospace, energy, military, medical, and advanced manufacturing fields have all already begun making important investments in next level coatings and polymers, as the power of breakthrough anti-corrosion and both self-assembling and self-healing hybrid biomaterials becomes apparent. Optical material manufacturers are another huge industry being serviced by these developments: optical sensors and 3D photonic structures are just a couple of advancements being designed as chemical materials obtained from biological sources, and the list goes on.

By sitting chemists and chemical engineers at the same table as cell biologists and geneticists, we are increasingly unlocking complex structures that tormented scientists for centuries, such as DNA, and converting chains into programmable “machines” that can accept or deny proteins they create, depending on our material needs.

Manufacturing elastomers and adhesives through greener processes than with polluting organic chemistry cracking is also becoming more commonplace, as we produce materials more similar to the wonders of nature than the traditional rugged substances made by man (check this article on the fascinating creation of synthetic spider silk by inserting the proteins into goat milk for a great example!). Finally, creating interesting camouflages through the design of materials with tunable properties, such as those observed in cephalopods (cuttlefish, octopuses, and squids) when under pursuit by a predator, is becoming a growing endeavor at the University of California.

But the obvious question presents itself – while all of these developments are intriguing, how far are we from seeing a widespread step-change in the industry, and from truly implementing the synthesis of these hybrid materials into our production plants?

The answer is a curious one…

The cross-discipline challenges and steps to come for advanced hybrid materials

Creating high cost, low volume products is always a risky investment of resources, and biomaterials are no exception. The required experiments and efforts in time alone are considerate, and the monetary cost is equally as significant. For this reason, synthetic biology and biomaterials alone are not the solution to our long-term problems.

The importance of blending this science with chemistry is straightforward – we are able to produce lower cost single and multi-component materials (the immense advantage of synthetic chemistry) by using the chassis materials and safe processes that biology offers. It is a matter not only of lowering cost, but of improving the final product significantly, using biology’s building blocks as an assembly line.

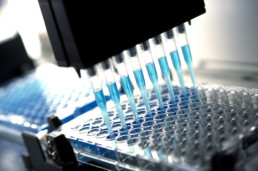

Furthermore, the great advantage of technology is that we are now able to integrate a shortcut to the synthesis and testing of new materials that was not present in previous eras: the introduction of concepts such as high throughput screening and combinatorial chemistry; stochastic learning; and both machine learning and data analysis is allowing for an immense increase in the acceleration of the Design, Build, Test, Learn cycle (or DBTL) that promote the acquisition of final products which are ready for client requirements.

In other words, by using tiny quantities of substances (picoliters) as the samples to be assayed (HTP rheology, tensile testing, small/wide angle X-ray scattering, light scattering, thermal characterization, and surface analysis, for example), with artificial intelligence and robotics behind each step of the process, laboratories can now go from a few dozen tests per day to several thousand daily assays. Thus, the correct sample – and therefore, the adequate molecule with the desired structural and functional properties – can be discovered in months, instead of years or decades, as previously.

Finally, by including the power of the technologically savvy (computer engineers and scientists) in the construction of biomaterial databases, we are expediting the creation of materials libraries, allowing companies to further incorporate the vast expanses of biological search space into materials science.

This is only possible by incorporating the vast knowledge of molecules contained in the minds of biologists and geneticists into the chemical manufacturing efforts of engineers and laboratory chemists – from any angle, it is a perfect cross-disciplinary blend that will ensure the future of a hybrid industry.

“We look at synthetic biology and everything it is bringing to humanity, and we have to accept what a marvel it has been.

However, the true solutions to many of our problems are not simply the complex materials you can manufacture from biological sources,

But instead, blending biology together with current chemical manufacturing processes and raw materials to synthesize molecules that take the best of both sciences. It is, after all, a perfect fusion.”

— Ryan Esner, Environmental Fluids CEO

Are we closer to perfection with biomaterials? Maybe, maybe not, but one thing is for sure – the combination of biomaterials and organic materials will ensure that we gain the best of both worlds and are able to produce much better substances for a world evolving towards renewable, multifunctional materials, clean processes and green chemistries.

As the advantages of these hybrid molecules in the materials science space become clear, manufacturers are rapidly gaining interest in the results of this fascinating fusion between biology and chemistry. The future is bright.